SEMI-AUTOMATIC DEMOLDING MACHINE

They are made in 2 models, for molds up to 400 mm long and up to 600 mm long. Both models are self-adjusting on height and transversal length, while the cross references on which to place the molds, inserted by the operator, must be adjusted manually.

A PLC allows the complete management of the machine.

Productivity is 250 to 360 molds /h, depending on the model.

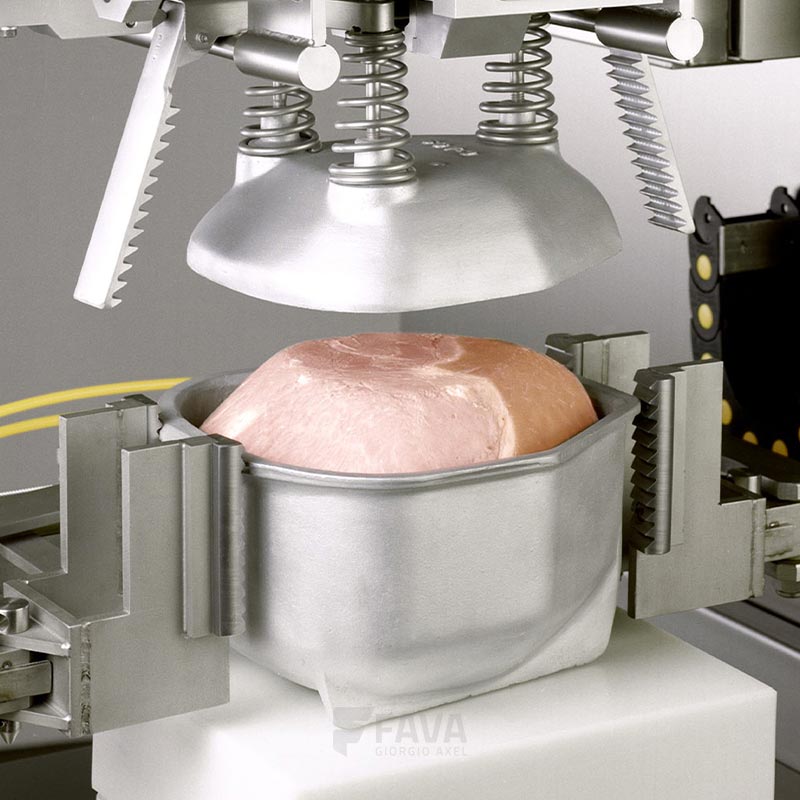

AUTOMATIC DEMOLDING MACHINE

The automatic mold removing machine can handle molds up to 400 mm or up to 600 mm long.

Loading is done by the operator, or by our feeding devices, onto the loading belt.

The machine measures the length of the mold, centering it longitudinally relative to the gripping head, which self-adjusts to the height of the mold by centering it transversally. The mold is then taken to the lid and product extraction station, the product is automatically sent to the downstream station, and the pot and lid are sent to the washing station.

A PLC manages the machine as a whole, and an operator panel allows the selection of recipes and makes the management of 3-spring molds equally simple.

Productivity is 400 to 480 pcs/h.

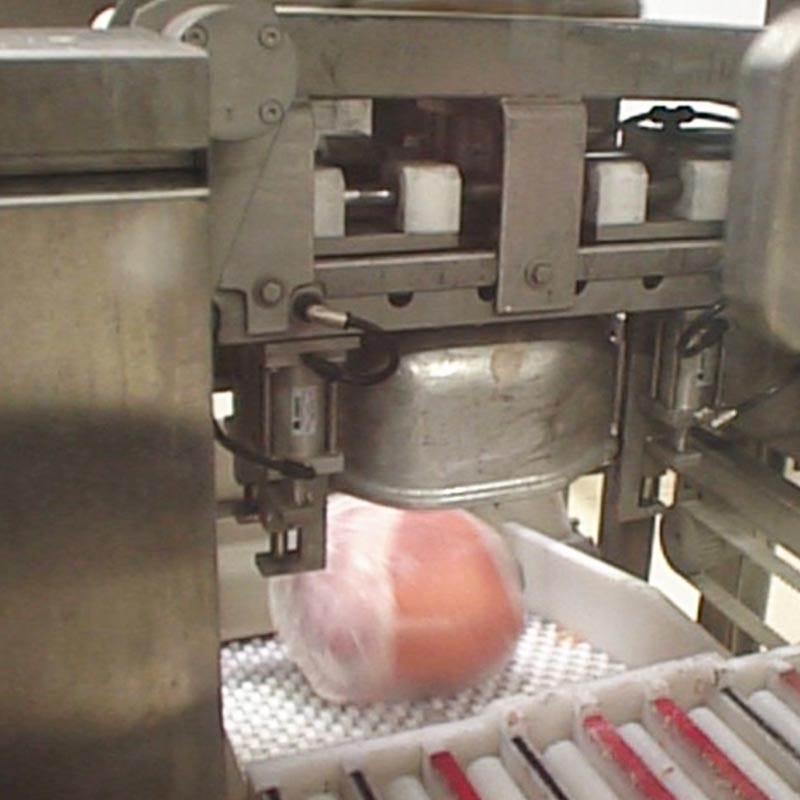

FAST DEMOLDING MACHINE

It derives from the automatic models and, thanks to the use of numerically controlled axes, allows perfect demolding with considerably higher productivity, up to 620 pcs/h.

Like the other models, it is equipped with a lid extraction device made with a divarication system that prevents damage to the handles.

Also extremely compact, with touch screen panel for easy operations.