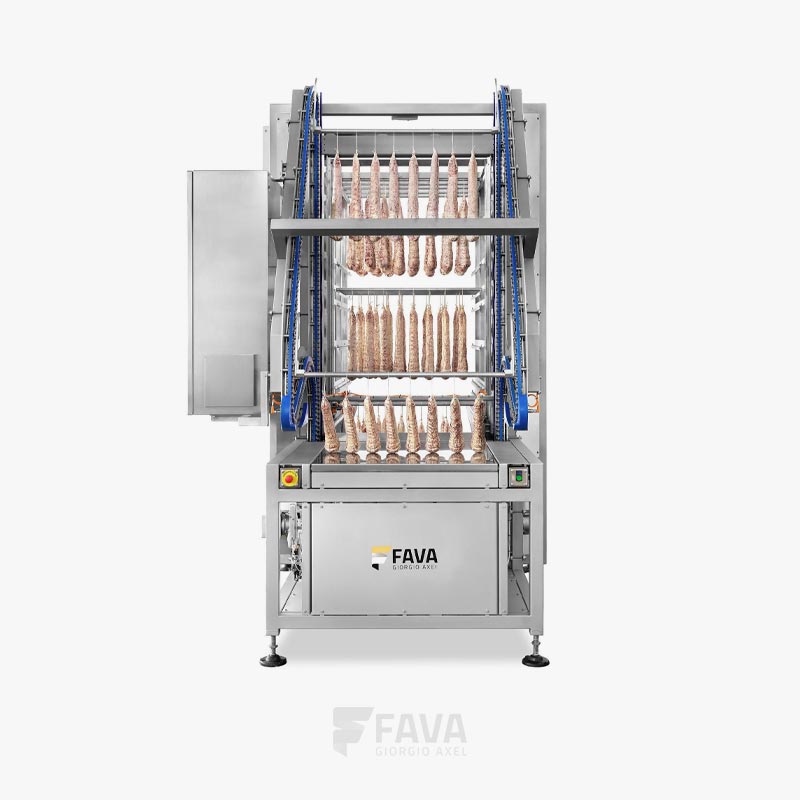

The compact loaders and unloaders for frames, trolleys, trees or suspended conveyors on which to place bars with hanging products can be fed either by manual product placement stations on the bars, by automatic loading devices for salami or other products on bars. We also offer a version that can be used both as a loader and an unloader.

The design, derived from our TFRC loading system, allows customizations depending on the length of the hanging bars (poles), the size of the frames (or trolleys or tees or suspended tray conveyors), and the size of the products.

In the case of semiautomatic loading, the insertion of the hanging bars into the loops is manual as is the effortless positioning into the hooks of the lifting catenary for subsequent storage in the programmed level. It is also possible to feed the loader with automatic salamis hanging machines to the bars.

All models move the arms that deposit the bars with the hanging cold cuts vertically, to adapt to the frames, which, with the same width, can have different heights and lengths, just as the heights of the levels to be loaded can be different, also depending on the product.

The compact loader, like the unloader, makes it possible to proceed with the formation of levels even while replacing a full frame with an empty one, of course in total safety.

Control PLC

A control panel with touch screen enables the operator to select operating modes, and the control PLC allows both connection with the company's production management system and remote connection with our technical support service.