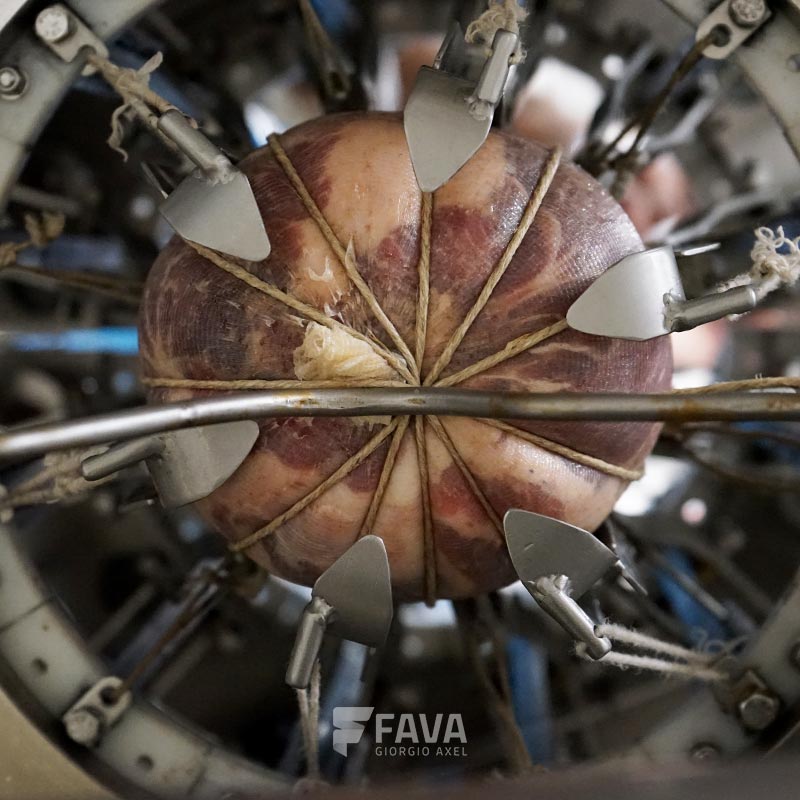

The IBR binding machine for coppa and rolled bacon makes the longitudinal binding necessary for hanging the product and to prevent indiscriminate stretching during helical binding. The IBR series can perform 8, 10, 12 and 14 rope tying, depending on the model.

The coppa, rolled bacon and pancetta coppata can have diameters between 90 mm and 150 mm, or between 70 mm and 130 mm, while the length can be up to 550 mm.

The machine is self-adjusting to the diameter and length of the product, and the productivity of the IBR10 model can be as high as 300 pcs/h, depending on the operators’ ability and ease of product handling.

Functioning

In the new models, the solenoid valves, control panel and electronic stop management device are at the top of the machine to facilitate sanitizing operations. In addition, the use of speed controls reduces noise considerably compared to previous models. An operator panel allows various parameters to be changed and stored in recipes and it is also possible to connect via Internet for remote technical service.

The IBR binding machine reproduces manual work, with the same aesthetic result, but with better regularity, enables high productivity and eliminates most of the risks from repeated movements.