In the LEGOSTAMPO system, molds are easy to move in molding and detaching lines. Automation is simple, reliable, economical, space-saving, the same for all models.

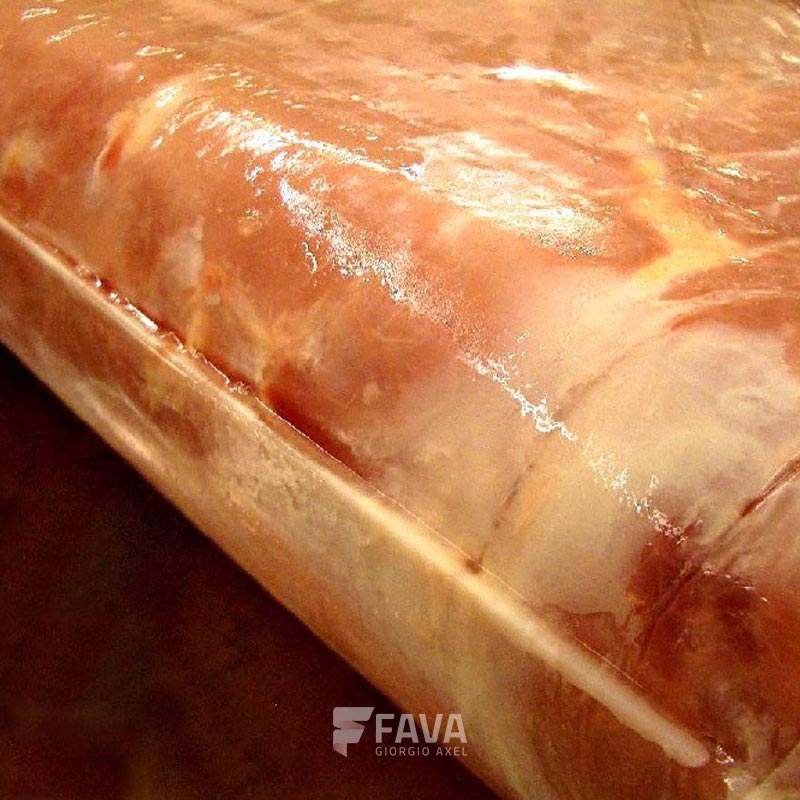

The stiffness of the molds ensures muscle contact at all points of the product, with slicing waste only at the ends.

The strength of the springs ensures that the rumps adhere even during and after cooking and cooling weight loss.

The molds are easy to stack in self-stabilizing piles that facilitate the circulation of steam, water, and cooling air in all directions, at all heights, for homogeneous cooking.

With LEGOSTAMPO, hams in logs for slicing and whole hams can be produced in the same plant, whether cooked in the traditional way, with weight loss, or vacuum bagged, in thermoformed, in clipped plastic casings, with and without weight loss, in steam or in water.

The different models are:

COMPOSED LEGOSTAMPO

with separate mold and lid, compensation and coupling systems in the heads, it can be pressed again, also suitable for research and development, can be used in piles or on overhead conveyor trays.

UNIQUE LEGOSTAMPO

with lid elastically connected to the bottom of the mold and with coupling and stabilization devices at the ends.

ZERO LEGOSTAMPO

with lid firmly attached to the bottom of the mold and with hooking and stabilizing devices at the ends, suitable for no weight loss products. Can be made with internal dividers and be supplied without lid for bacon and pate.

MULTIS LEGOSTAMPO

for producing whole products with traditional shape in " composed" and "unique" versions.