Hand-operated slice cutting machine

For caciotta or pecorino cheese wheels, cut into 4, 6, 8, … portions. The cheese, placed on the cutting block, is automatically centered with respect to the cutting blades, attached to a ring moved vertically by hydraulic actuators (constant speed whatever the hardness of the product). Cutting can be implemented with stainless steel wires. Adjustments are simple and quick.

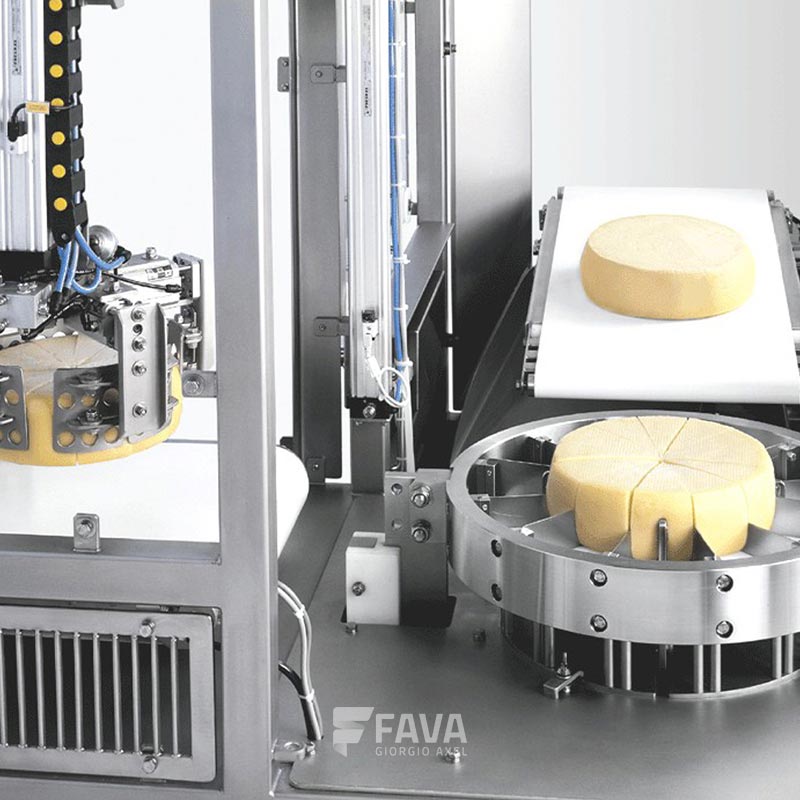

Automatic slice cutter

With loading belt that transfers products to the cutting block; an ejector, or mobile gripper, allows the cut product to be transferred outside, with automatic loading of the new product.

Slice cutters for large cheeses

are made in such a way as to obtain disks that are automatically loaded onto the slice log. The thickness of the disk is defined by the diameter of the product, measured continuously, and the desired weight. Flush cutting is used for disks of vertical-axis cheeses, such as pecorino romano, while for horizontal-axis cheeses, such as provolone, the disks are made with specially shaped, hydraulically driven blades.

Transverse and longitudinal cutting

Used for horizontal-axis products to obtain semi-cylindrical portions that can be portioned into half-disks or to be sliced. Depending on the hardness, either flush or blade cutting is used.

Cutting into blocks

Is performed using products of similar shape and cutting is done by passing the product through wire grids, with horizontal and vertical axes, suitably positioned, according to orthogonal directions. Product handling is performed using controlled axes.

Ultrasonic cutting

Ultrasonic cutting is used for difficult products such as cheeses such as brie, gorgonzola, Roquefort; sweet or savory pies, fresh or frozen; cooked ground meats or vegan products; stuffed pastas; tuna fillets for potting, and more.

The best results are achieved by moving the ultrasonic blades with controlled axes or with 4-, 5-, or 6-axis robots, both for cutting quality and operating flexibility.