Cross-cutting in half

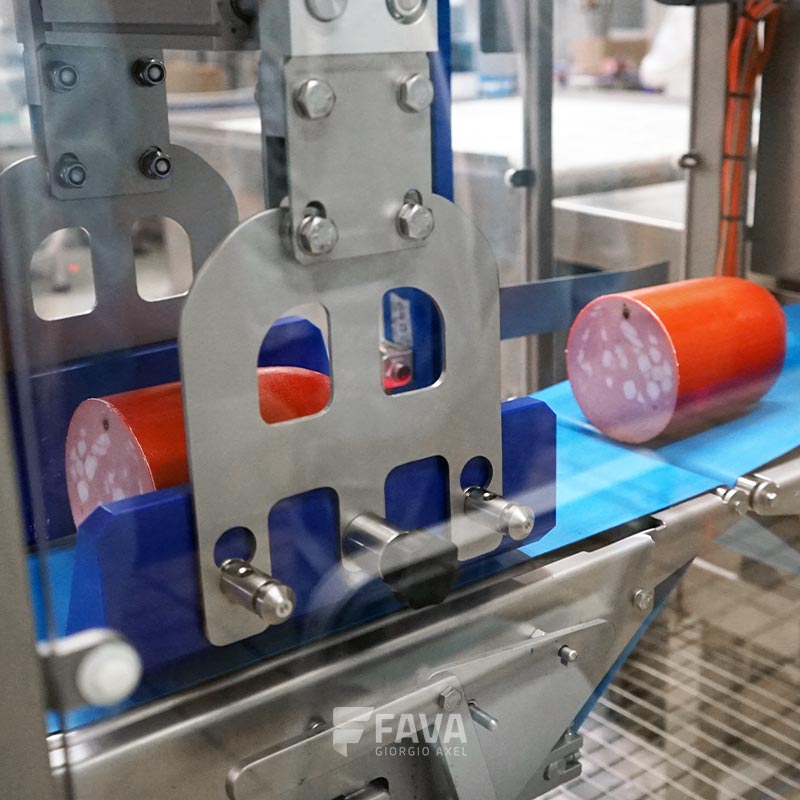

Our machines, made in a variety of models, perform half-cutting of mortadella or other coarsely cylindrical shaped products, for sizes between 5 and 50 kilograms, as well as cutting side-by-side products, such as salami, or for whole products such as speck or cooked products. The loading belt, which can be conformed flat or V-shaped, facilitates directionally correct insertion of the products to be cut, to obtain a cut orthogonal to the longitudinal axis of the product.

The machine is self-adjusting on the product and is equipped with a special profile blade that performs the perfect cut without imperfection or laceration of any type of casing.

The machine can be equipped with a rotating device to orient one of the two halves to facilitate bagging, either manually or automatically as, for example, done using our robotic islands.

Slice cutting

A machine version with cross-cutting, with or without automatic loading, makes disks of mortadella (Bologna sausage) that are then portioned into halves, quarters or sixths. A special sensor continuously measures the diameter of the product, at the variation of which the thickness of the disk to be obtained is calculated, in order to approach the fixed weight. Length is defined thanks to suitable measuring device and the cut made with a special profile blade.

The same machine can be used for cutting in half, as well as for longitudinal cutting with a horizontal blade.

Longitudinal cutting

Longitudinal cutting machines consist of a housing with centering of the product, which is pushed through a vertical blade; the solution adopted is not affected by any conicity of the products, and a downstream belt receives the two halves.