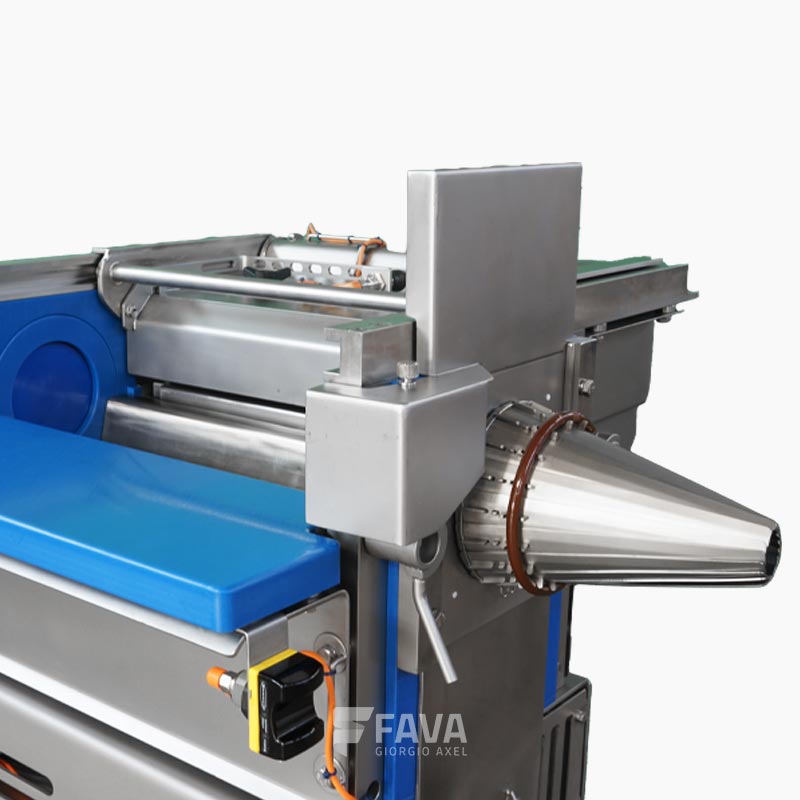

Machine for modeling and casing coppa, pancetta (rolled bacon), pancetta coppata, bresaola, loins, roasts, individually or compounded to be sliced later.

The product is fed into an open-top mold, and the machine’s construction features allow for perfect compacting and stuffing of whole or rolled products, partly due to the automatic flattening of the tips.

The operator holding the casing has to make minimal effort due to the special construction of the anti-spill funnel, with natural or synthetic casing, whatever the length of the product.

The molds are easily removable and separable, and their open design facilitates washing operations, also ensuring the absence of bacterial growth over time.

Productivity

Products from 80 mm to 150 mm in diameter can be processed, and the mold lengths, in the various models, are 500 mm, 950 mm and 1,100 mm. Real productivity, on a daily average, ranges from 120 to 300 pieces/hour, depending on the model and product.

The new model of MIN-A modeling-casing machine has automatic closing and opening of the loading area. Once the product is inserted, the operator only has to touch with a finger, even wearing latex gloves, the special sensor and thus activate the closing of the loading tank with start of the molding and casing cycle (round shape, flattened tips and better adhesion in the case of introduction of more pieces), according to regulated times and managed by the control PLC; allowing the operator to calmly put on the casing and hold it on the anti-fatigue funnel.

At the end of the cycle, the door automatically reopens for loading the next product.