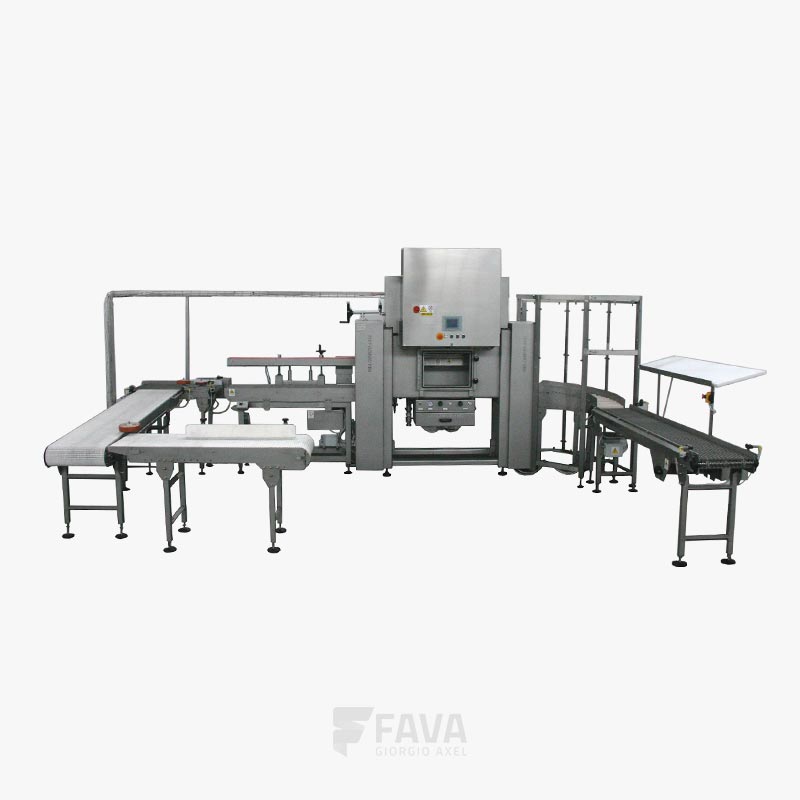

Our molding lines, designed and manufactured according to specific requirements, include the section for placing the meats in the molds, which are then de-aerated, or vacuum heat-sealed, and then pressed and placed on the frames, trolleys or overhead conveyors to be sent to the cooking units.

The massaged product is transferred to one or more receiving tanks from which the product, whether whole or composed, is taken to be placed in the molds, with or without weight control.

The molds are transferred to workstations, whether single or sequential, to be conveyed to downstream stations under the best ergonomic conditions.

Best organoleptic quality

The products, with Cartene or in heat-sealable bags, are deaerated and vacuum-treated passing through our treatment tunnels to obtain the best organoleptic quality. After an operator places the appropriate lid, the molds pass through our automatic mold presses and then are placed on the cooking frames, trolleys or overhead conveyors, even through the action of our facilitators or automatic mold loaders.

After cooking in steam ovens with cooling in cold storage (or in our cooking and cooling units for vacuum-cooked products) the molds will pass through our de-molding machines and the finished product will be vacuum bagged and packaged by our own machines before passing through our continuous pasteurizer-coolers.

Our systems can be designed for both traditional molds and our Legostampo systems.