PASTEURIZER AND COOLER

Our pasteurization systems transport vacuum-packed cooked hams on conveyor belts, arranged on one or two levels, or on racks moved by chain-driven transmissions with high-efficiency motors, ensuring continuous transfer first through the hot section and then through the cooling section. This configuration allows vertical development, reducing the plant footprint. Loading can be either automatic or manual.

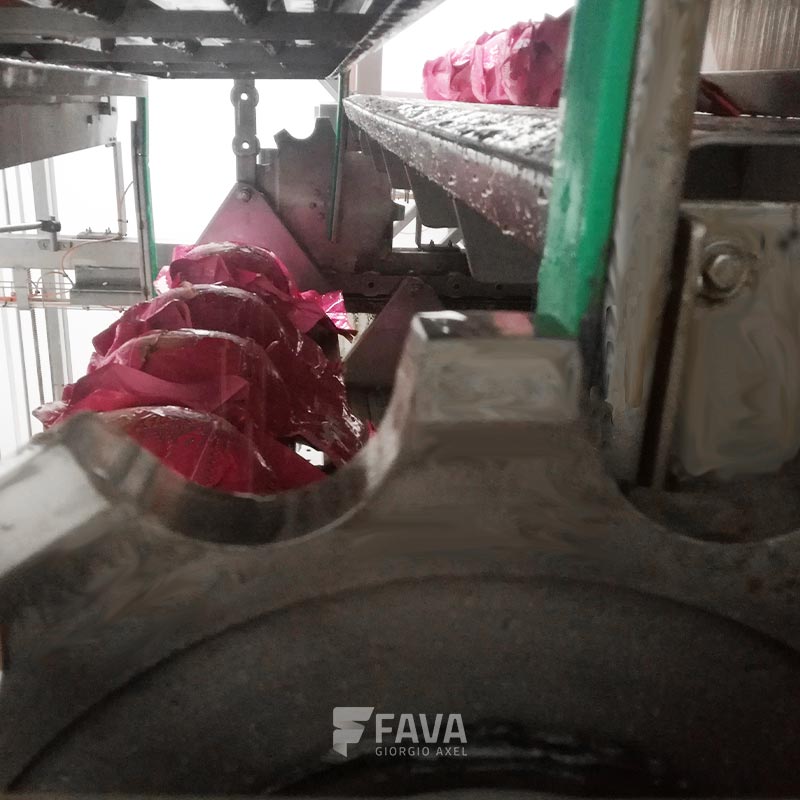

In the movable-tray configuration, the action of spray showers positioned above and below the products, both in the pasteurization and cooling sections, ensures uniform surface treatment even in the presence of the flaps of aluminum bags.

Thermal insulation, large-surface heat exchangers, high pump flow rates, and the use of high-efficiency motors minimize energy consumption while maintaining the same pasteurization effectiveness.

PACKAGE DRYING SYSTEM

For weighing, labeling and wrapping products immediately after processing, we propose drying devices including jets of compressed air and blowers in a tunnel crossed by a conveyor belt, containing noise and without discharging cooled, therefore expensive, air to the outside.

PRE-PACKAGING HEATER

Vacuum-cooked products are often taken out of cooking packages, also to remove the gelatin. Our automatic heater dips the shelves with single products into a vertically developed tank, making the gelatin liquid and easily removable. The system can be completed by a tunnel for drying and cooling the products before bagging.