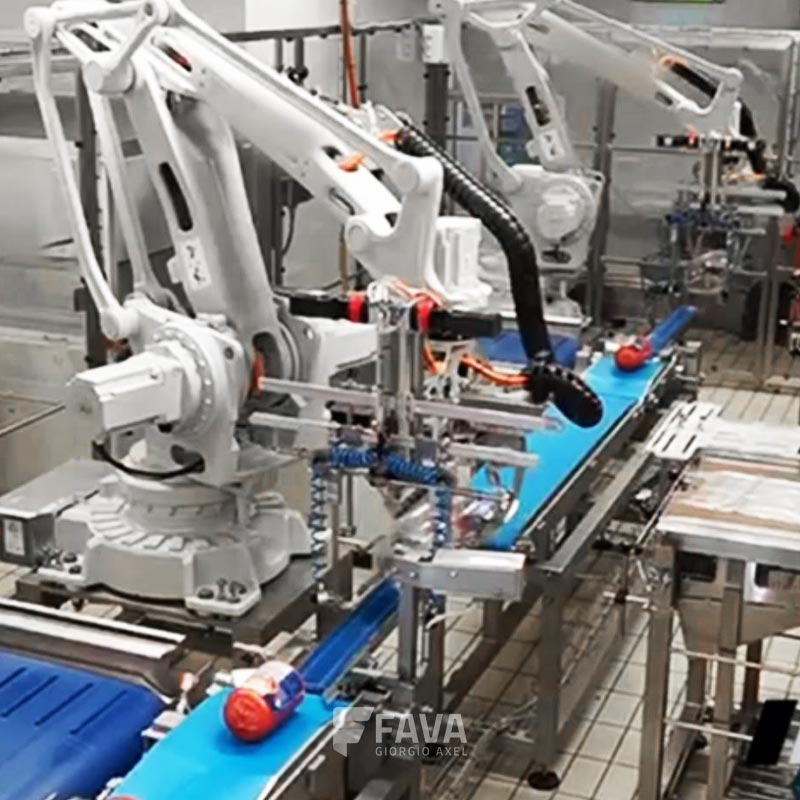

Wave-cut product loading

4- or 6-axis robots pick up several slices at a time from the conveying and sorting belts using easily sanitized suction cup gripping devices to introduce them into the thermoformed tray without damaging the products.

The belts are fed by our wave-cut portioning machines. Other gripping devices enable the loading of different products, such as roasts in pieces, with horizontal or vertical axis, or cheeses or more.

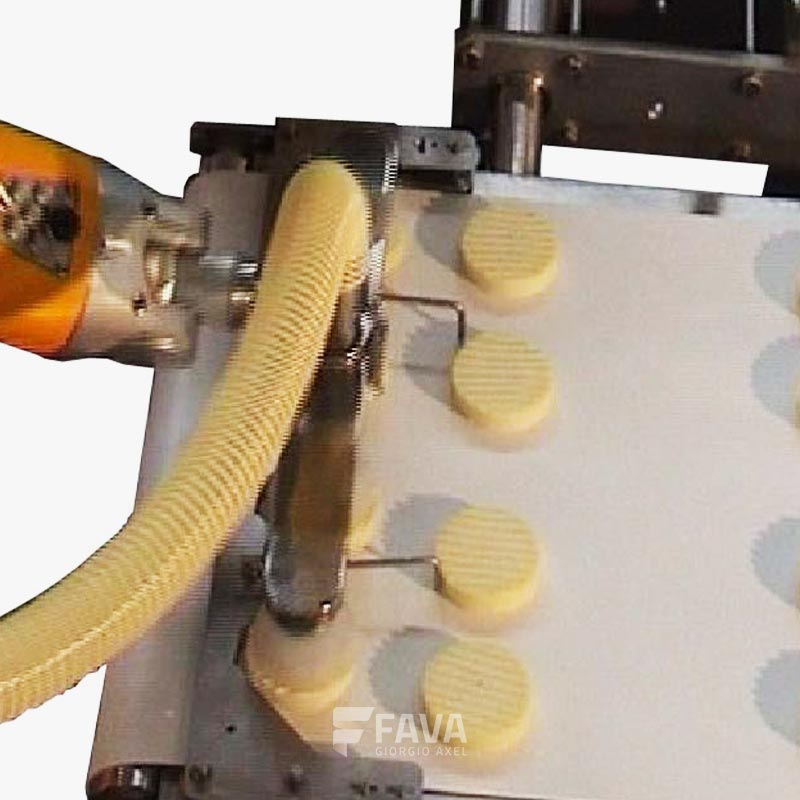

Product loading in wedges

Our mortadella or cheese portioning machines neatly deliver sliced discs individually placed in the thermoformed tray by parallel or scara robots.

Robotic bagging

It is possible to handle without staff products of different sizes and shapes, such as mortadella or cheeses, including from our cutting machines, in the same plant to bag them and place them on the vacuum thermoforming machines using 4-axis robots equipped with self-adjusting grippers.

Ultrasonic cutting

Ultrasonic cutting is used for difficult products such as sweet or savory pies, fresh or frozen; cheeses such as brie, gorgonzola, Roquefort; cooked ground meats or vegan products; stuffed pastas; tuna fillets for potting, and more.

The best results are achieved by moving the ultrasonic blades with controlled axes or with 4-, 5-, or 6-axis robots, both for cutting quality and operating flexibility.

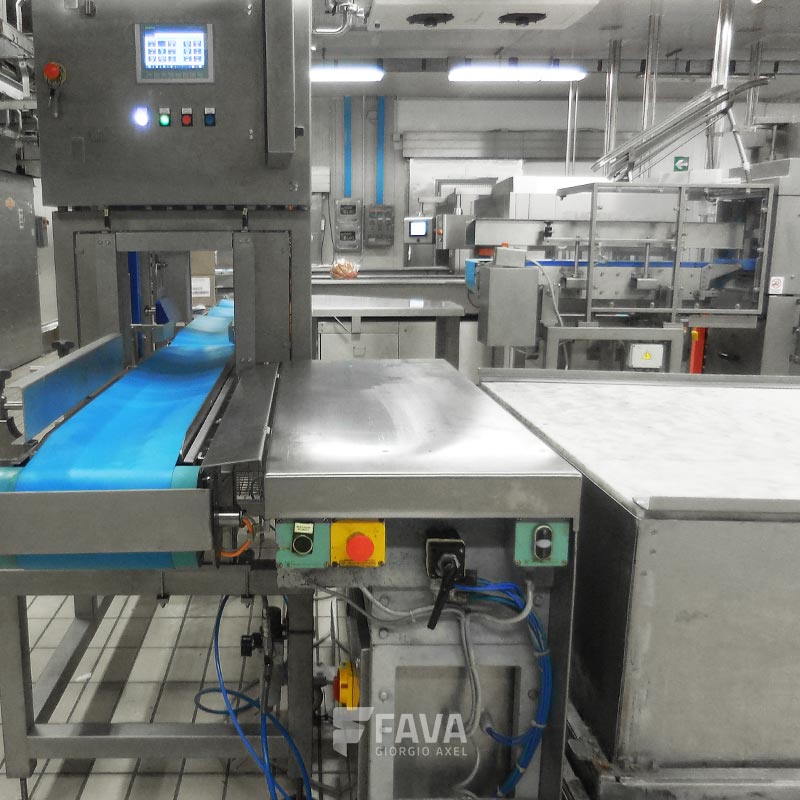

Conveyor belts

Our lines often require conveyor belts to handle naked or packaged products, molds and Legostampo, and whole or to be sliced deli meats. Our belts strictly comply with safety regulations and are easily sanitized in all their parts.