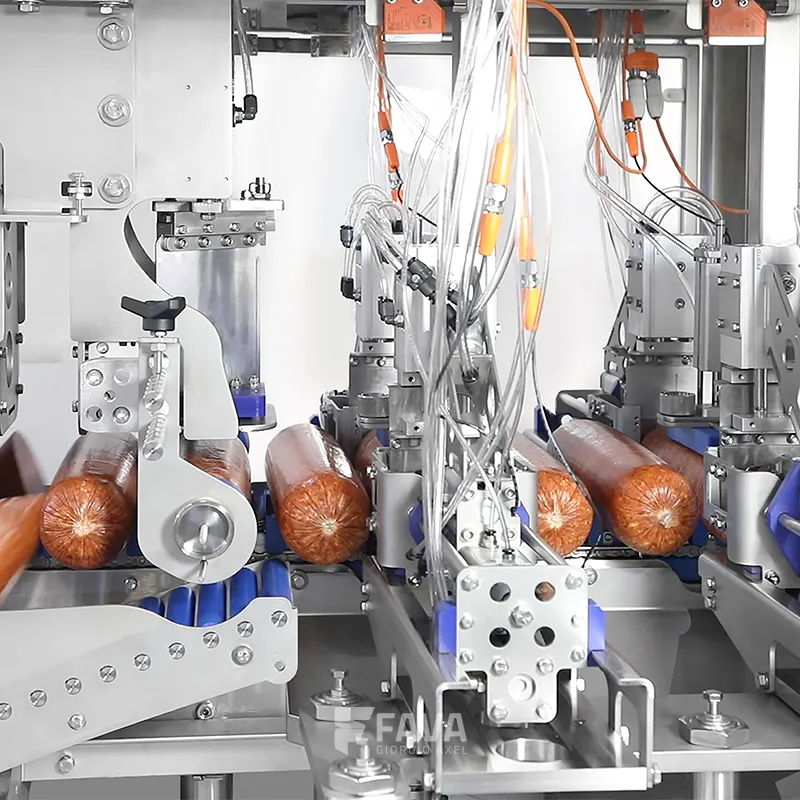

The convenient loading belt, which can be fed by an automatic device, allows for precise positioning of the products in the clip removing station(s).

In each station, the clip removing heads rest on the workpiece, minimizing product removal for the best aesthetic result, even in the presence of partially recessed clips.

The products are then transferred to the cutting device, if present, which divides them into two parts of equal length and/or equal weight, depending on the characteristics of the product, and then transfers them to the next processing stages.

The products can have a diameter from 30 mm to 240 mm and a length of 250 mm to 1,200 mm, depending on the model, and a productivity of 15 to 60 pcs/min.

Control PLC

An operator panel enables machine management and provides operators with information for operation and maintenance. The control PLC allows connection with the company's management system, for production scheduling and product tracking, and with our remote technical support service.