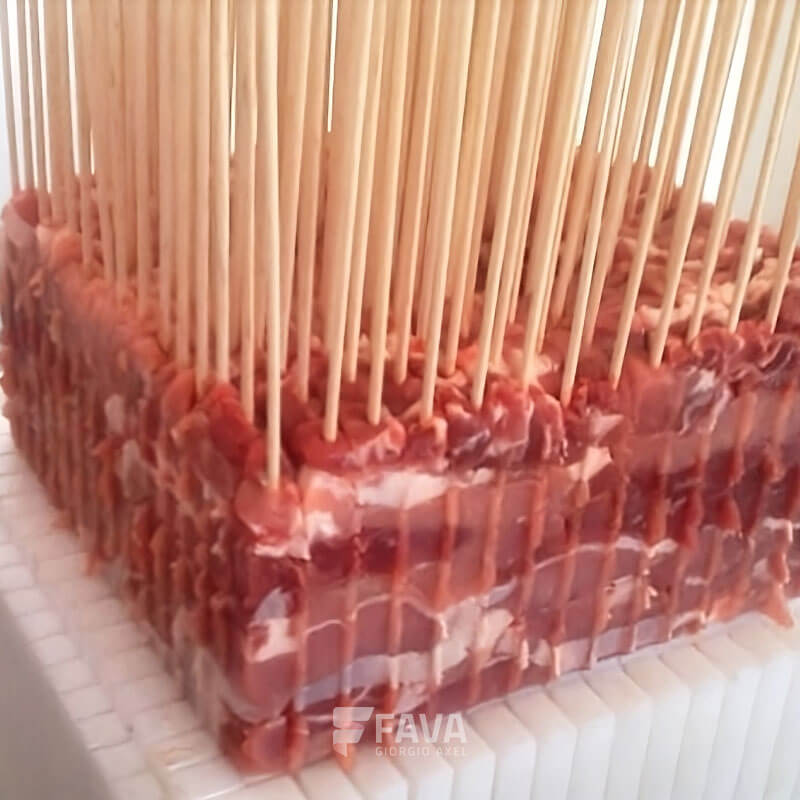

The SPDCSA skewering machine uses straight sticks, , with a diameter from 3 to 3,5 mm, length from 200 to 250 mm, with or without tips, depending on the length of the kebabs. Picking of the sticks from the special storage, which can be loaded without stopping the machine, is automatic, and the presence of the sticks in the corresponding pits is checked.

In the universal version it is possible to use molds for products 110 mm and 160 mm long, according to the section indicated in the dimensional table in the information sheet, and the detection of the molds used is automatic.

The molds, made of plastic material suitable for food contact and stainless steel, are easily disassembled for washing operations.

The productivity of the machine depends on the number of sticks to be inserted and the cutting length; thus, it is possible to reach the real productivity of 22 to 24 molds/hour in the case of small kebabs having dimensions 14 x 14 mm (till 5,400 /h), while it is possible to produce up to 38 to 40 molds/hour in the case of 28 x 28 mm skewers (till 2,560 /h)..

Operator panel

The touch panel interfaces with a PLC that allows storage of operating parameters, which can be recorded in recipes, and enables connection with the company's management system and our remote technical support service.

The SPCSA is offered in versions for arrosticini only (14, 16 and 20 mm per side, length 100 mm), for skewers only (20, 25, 28 and 32 mm per side, length 160 mm), or universal.

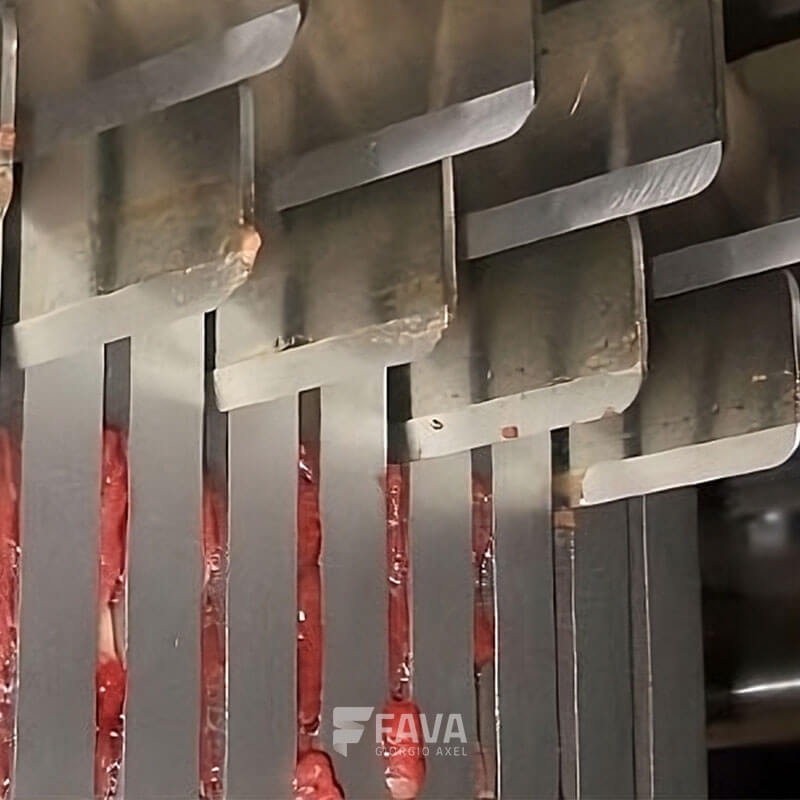

All versions can be equipped with a pneumatic device for extracting the products from the mold, also using a convenient stainless steel band for total extraction of the skewers, or arrosticini, from the mold base plate.