ILS series tenderizers are made completely of stainless steel and plastic material suitable for food contact.

They can be easily inserted into production lines, normally downstream of injectors, but they allow the treatment of product that has not been injected and then placed in tumbler to absorb the added brine.

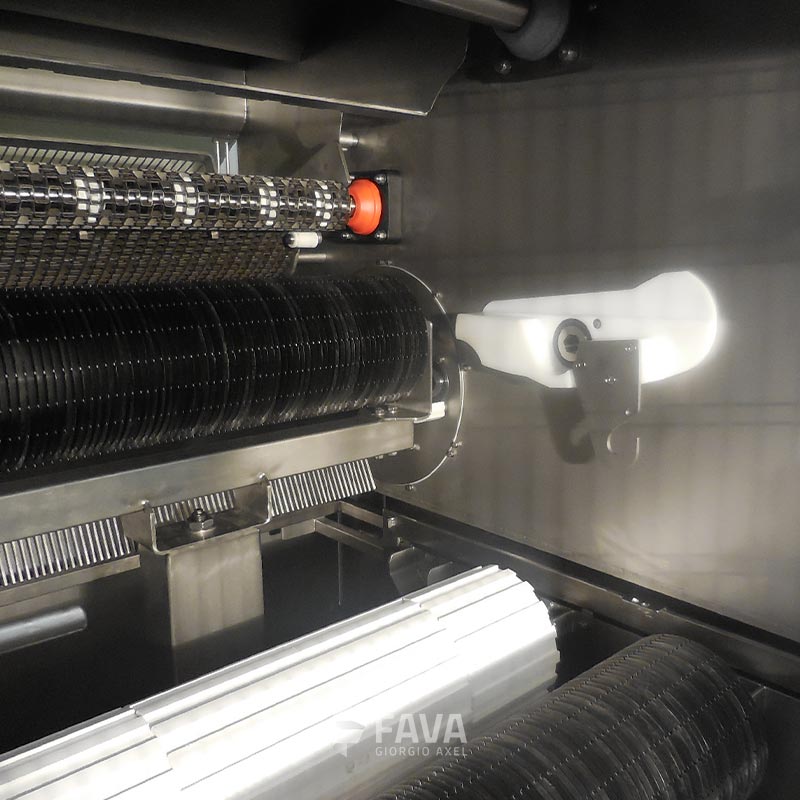

A pair of motorized shafts, with adjustable speed, self-adjusts to the thickness of the product being cut and etched on both faces, greatly increasing the absorption surface area of brines and additives, aiding the extraction of soluble salt proteins and reducing massaging time.

Functioning

The cutting pressure is pneumatically adjusted to define the depth of tenderizing and meet different technological requirements. The size and design of the blades prevent the deposit of aponeurosis on the cutting profile, ensuring that the best performance is maintained throughout the work shift and over time. The pitch of the cutting blades is chosen according to the characteristics of the product, initial and final.

Products with rind can also be processed by replacing the inner blade pack with a food-grade plastic roller.

The feed belt of ILS carve macerators can be either 400 mm or 600 mm wide. The ILS-COMBI model has automatically interchangeable blade packs for greater production flexibility.