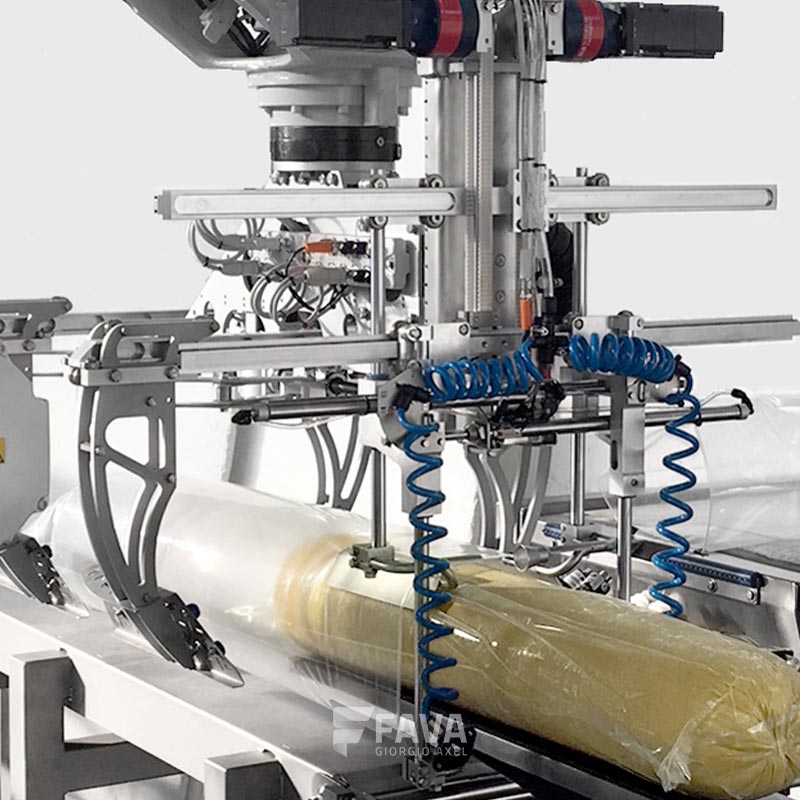

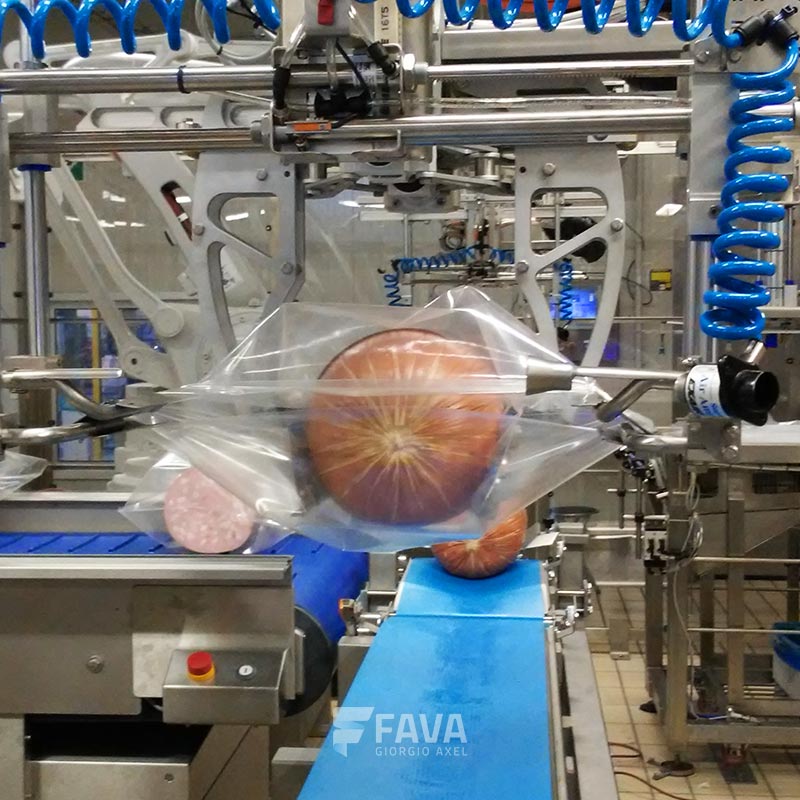

The key element of our custom-made robotic islands is the special grasper (patented), which unifies the functions of gripping the packaging bag, whether from storage or from unwinders for taped bags, handling the bag mouth and gripping the product for its ordered transfer onto the belt of vacuum chamber machines.

Products stop on thin belts, which have a particularly small footprint in both width and thickness, quite similar to those of our bagging helpers. The bag mouth can be conformed to 4-, or 8-, or 12-sides, depending on the gripper chosen according to the shape and size of the products, whether mortadella, sliced cheese logs, or other.

Functioning

The gripper itself is capable of flattening the mouth, when deposited on the vacuum machine belt, to make subsequent sealing easy and reliable.

The high adaptability makes it possible to optimize the size of the bags in order to reduce and minimize the use of plastic material.

The graspers are easily interchangeable to allow the handling of products from 100 mm to 290 mm in diameter, just as the gripper part is modular so that it can pick up products from 0.3 to 1.2 m long and beyond.

Depending on the required productivity, two robots can load the same double sealing bar machine, with a productivity of up to 720 pcs/h, or 2 machines side by side.

We also propose solutions suitable for handling flow-packed products.