Our UCR cooking and/or cooling units for meat and vegan products are basically tanks that are closed at the top and have doors at the ends that allow the handling of trolleys or stacks of molds, such as in our Legostampo system, similar to steam ovens. During cooking, the improved efficiency of heat transfer to the products, together with the lower heat loss and the recirculation and storage of treatment water, allow very high energy savings.

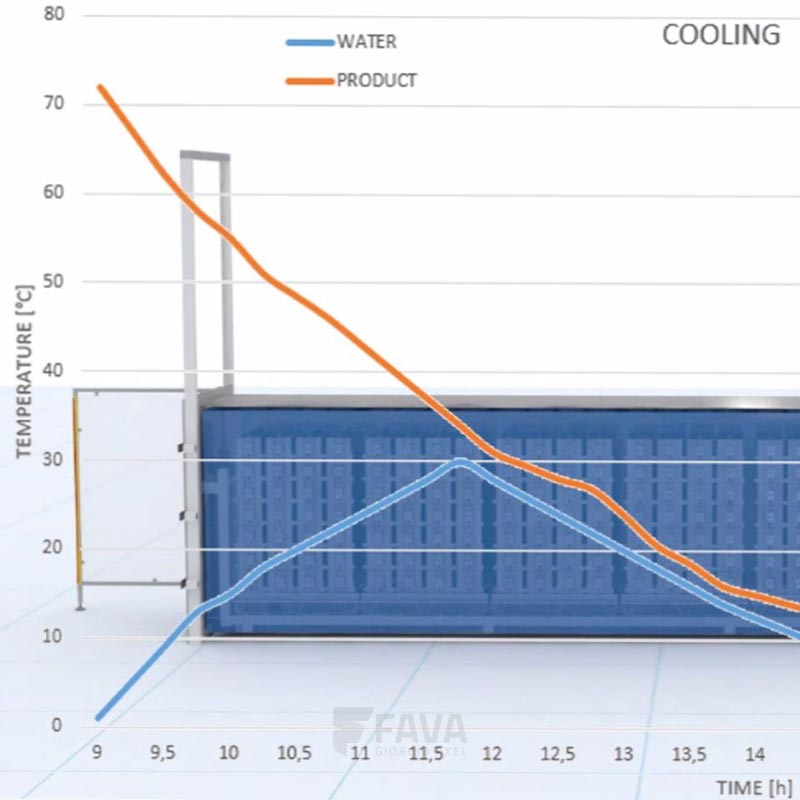

During cooling, the use of water optimizes heat transfer and allows the product temperature to be reduced more rapidly, resulting in considerable energy savings compared to different solutions in use.

Our integrated cooking and cooling units drastically reduce cooking and cooling times, allowing the best utilization of the holding molds or equipment used. The same applies to cooling units intended for processed cheese, or similar products.

Other benefits of the system we propose are a reduction in space requirements (two rooms in one) and the elimination of moving trolleys or stacks of molds from one room to another (logistical benefit), as well as improved energy efficiency.

integration with the handling systems

Our UCR processing units integrate perfectly with the handling systems used for regular steam ovens,to which they can be placed side by side, and make it easy to use trolleys and frames to transport products, in molds or handled differently, whether they are destined for sale or for slicing lines (Legostampo system).