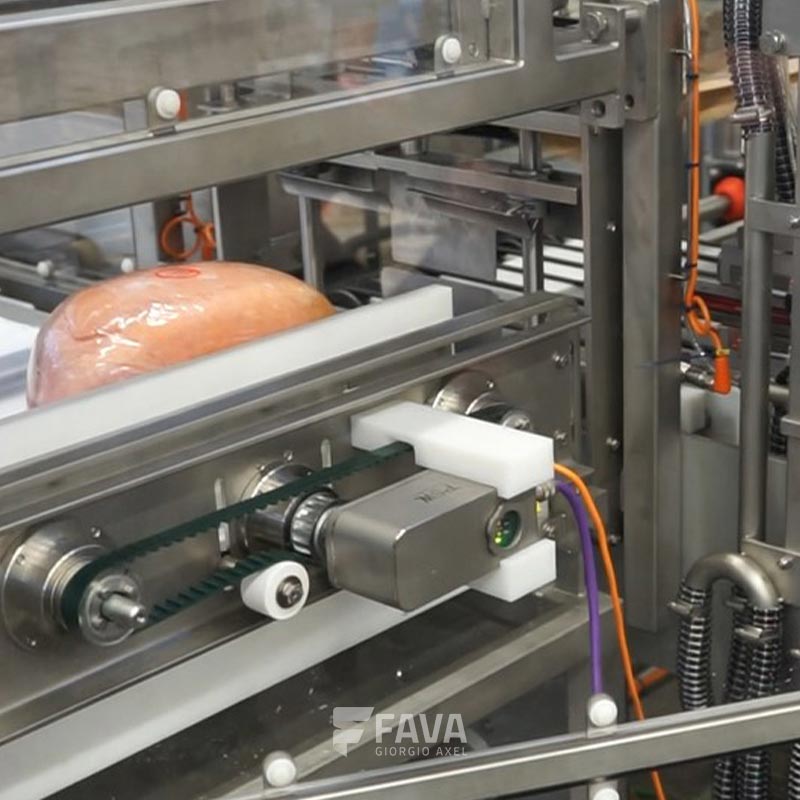

The first machine in our vacuum packaging line is the bagging machine, with productivity from 360 to 720 products/h.

The bag, or sack, stacked in the adjustable storage, is automatically picked up and positioned so that the arms of the opening device, which are adjustable, give the mouth the correct shape for introduction, protecting the sealing area, a particularly important aspect for cooked hams and similar products.

A closing device on the package mouth flattens it, preventing its natural reopening, preparing it without folds for vacuum heat-sealing.

Functioning

The products pass on an accumulating belt for subsequent transfer to our vacuum heat-sealing tunnel, with automatic inlet and outlet opening and right or left loading direction, as it is for the bagger. The loading and unloading doors move vertically without creeping on the seals, ensuring maximum vacuum level and low maintenance requirements.