Functioning

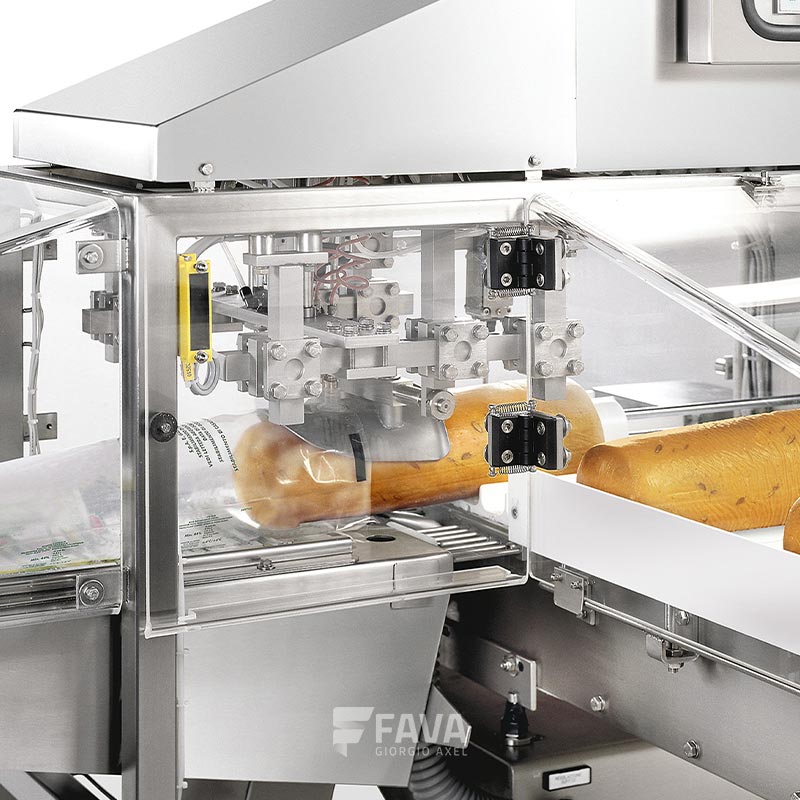

The advancement device drags the bag, which rests on the product by wrapping it, to fit into an in-line vacuum heat sealer with a head sealing bar, such as our TSVCC (also usable for flow pack products), which still minimizes surplus while allowing high productivity. Another solution, particularly suitable for products up to 80 cm long and transversely stable, involves a diverter that operates in synchronism with the conveyor belt of a lid vacuum heat-sealing machine with belt.

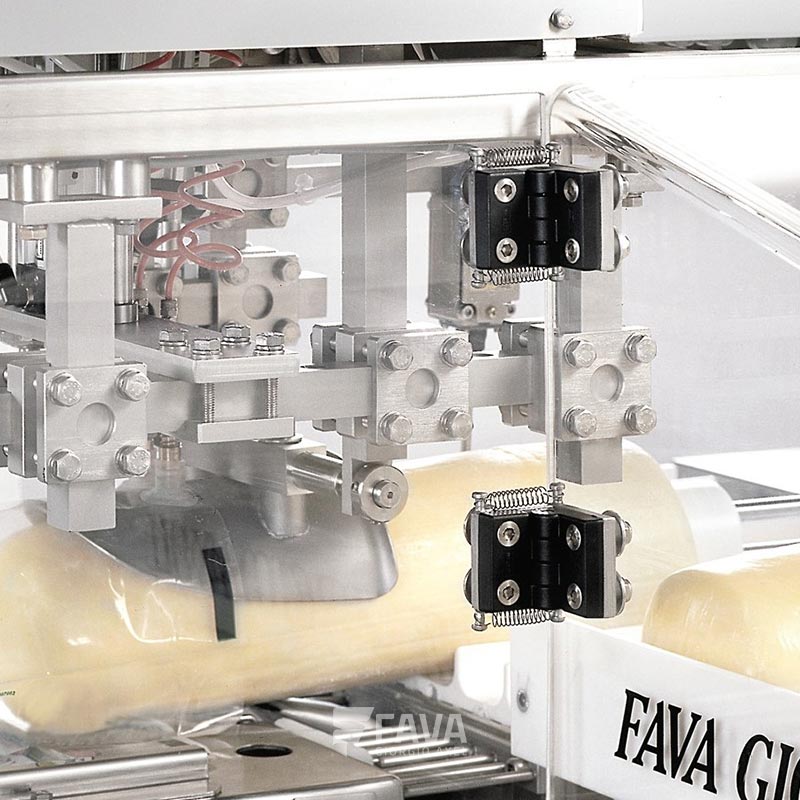

We also propose a robotic solution,for automatic packaging and loading of belt machines, with a grasper for gripping the taped bags with a 12 “sides” conformation, which most closely approximates the round section of the product, or with 4 sides, in any case capable of flattening the mouth to prepare it for heat-sealing.

To complete our offer, we produce an automatic packaging machine with high productivity (up to 900 pcs/h), using taped bags and particularly suitable for medium-length products.