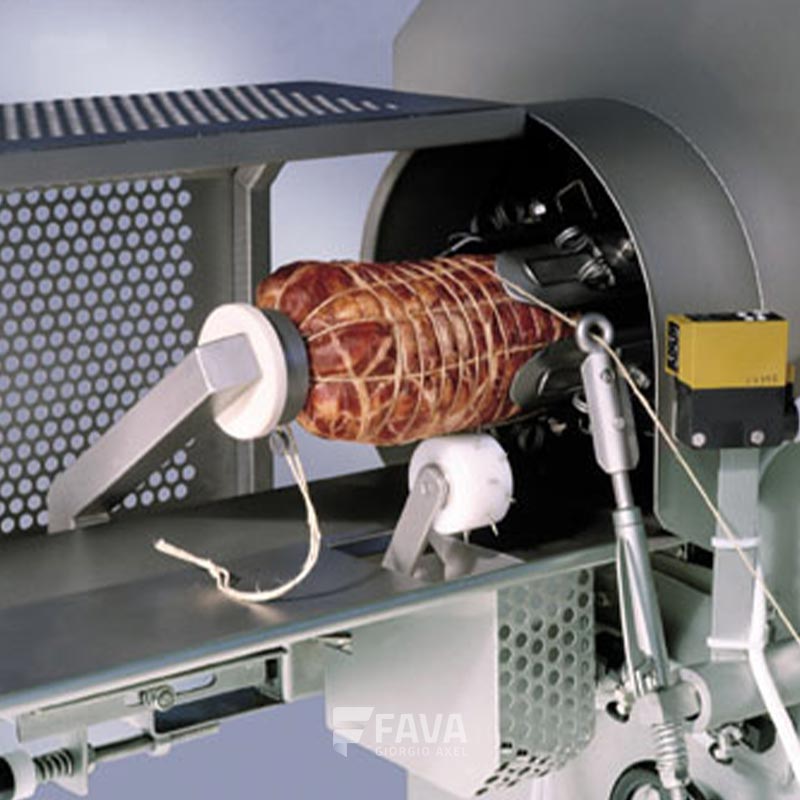

The LCP-F binding machine performs helical tying, and casing piercing, of coppa, bacon, fiocchi, etc.

The products can be between 80 mm and 150 mm in diameter, while the length can be up to 480 mm, and the binding machine is self-adjusting on diameter and length.

The machine is suitable for all types of casings, both natural and synthetic, and can tie coppa, including paper or with “canes,” bacons with rind or in natural or synthetic casings, and bacons with a coppa inside, whether in synthetic or paper casings. It is also possible to tie fiocchi, culatelli, loins, etc.

Functioning

The LCP binding machine can use natural or elastic rope, allows the adjustment of the number of initial and final spirals, the tying pitch, the pull of the rope, therefore the tightening of the product, which is done in progression to give the product the required and correct cylindrical shape. The aesthetic result is quite similar to that obtainable with traditional manual tying. It is possible to tie up to 300 coppa/h, with the required pitch for Parma and Piacenza cups, and more generally, productivity depends on the binding machine model, product length and tying pitch, as well as the skill of the operator.

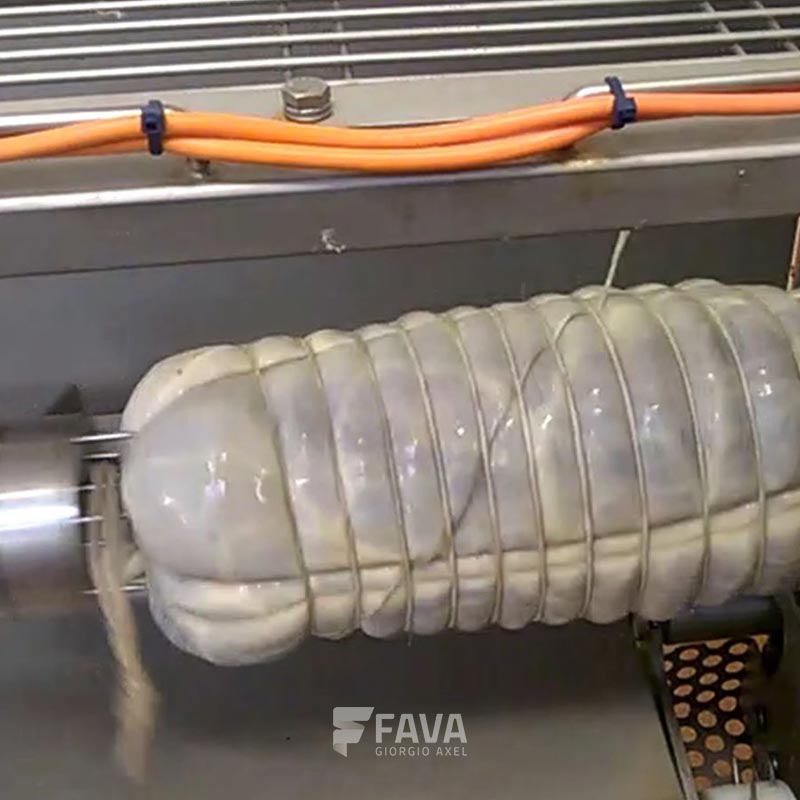

AUTOMATIC BINDING MACHINE FOR COPPA AND ROLLED BACON

The LCP-F-A binding machine, derived from the basic model, is equipped with a feed belt that is loaded by the operator in charge of the IBR longitudinal binding machine. Self-adjusting on product diameter and length, it uses only natural rope.

The tied product is unloaded onto a roller conveyor that transfers it to the processing to be carried out downstream.

The operator panel allows the machine to be adjusted, storing its functions, and the management PLC can be connected via Internet for remote technical assistance.