Our MIN-L stuffing and casing machines for long products are advantageously used for products to be sliced composed of several whole products. The products to be sliced, with particular reference to coppa, bresaola, loins, and pancetta, are placed in a single casing, and for our competing machines, it is the downstream clipping machine that, by pulling the casing, longitudinally compacts the product.

The adhesion between the ends of products thus depends on many variables, such as the size and temperature of the products, the irregularity of the ends, the size and softness of the casing, and more; consequently, it is necessary to use additives that allow, sometimes even by reaching higher temperatures during drying, to solve these problems as much as possible.

Our MIN-L stuffing and casing machine does not require additives of any kind to ensure adhesion between products, meaning products can be salted in the traditional way, even with lower salt content as is the case with our salting-massaging machines.

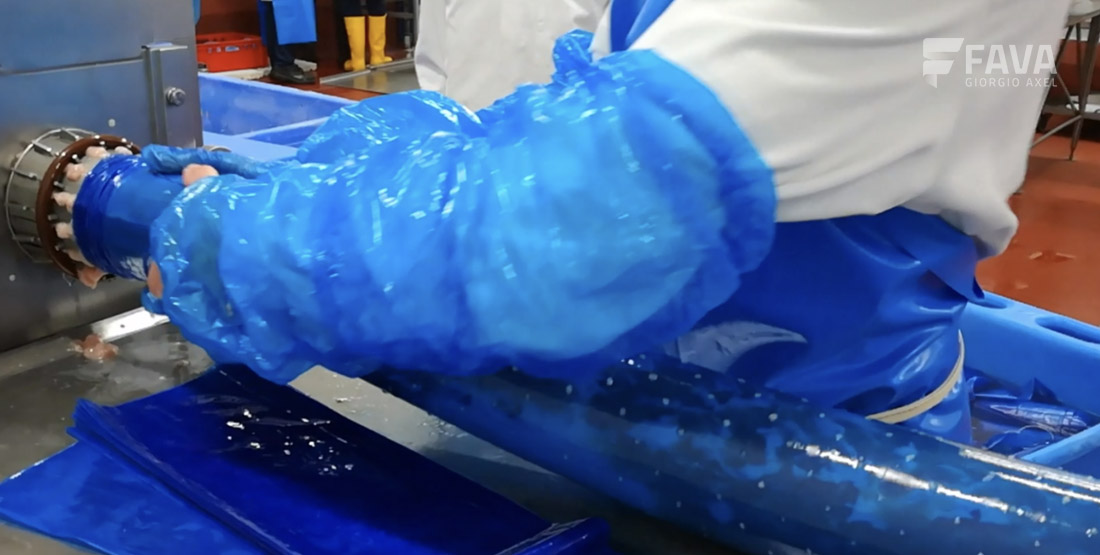

Thanks to design and construction choices, our stuffing and casing machines realize high hydrostatic pressure that does not damage the product, compacting it before inserting it into the casing. As in all our models of stuffing and casing machines, MIN-A and MIN-L, the conformation of our funnel holds the casing in the stuffing stage, without requiring any effort for the operator, and as is well known better ergonomics corresponds to higher productivity.